Ted Baker approached Lil Packaging to eliminate risk of Far Eastern sourcing whilst seeking alternatives to plastic wrapping its web boxes.

The Challenge

Founded by Ray Kelvin in 1988 in Glasgow, Ted Baker is a quintessentially British, global lifestyle fashion brand offering menswear, womenswear, accessories and everything in between. The brand is famed for its quirky, distinctive use of pattern & colour and irreverent sense of humour.

The Problem

“We need you to ‘Ted up’ our packaging”

Knowing that Ted Baker was making huge commitments to improved sustainability, a meeting was arranged at Ted HQ’s ‘Ugly Brown Building’ where our company owner Fred Lill identified two areas in need of significant improvement and posed the question "Should Ted do it that way?"

- Ted’s Web boxes were previously being made in China and gloss laminated in plastic

- All web orders were previously passed-through a poly flow-wrapping heat shrink tunnel.

Ted Baker wanted Lil to deliver something out of the ordinary. Distribution Director Laurence Connolly opening brief was simply that “We need you to ‘Ted up’ our packaging.”

The Solution

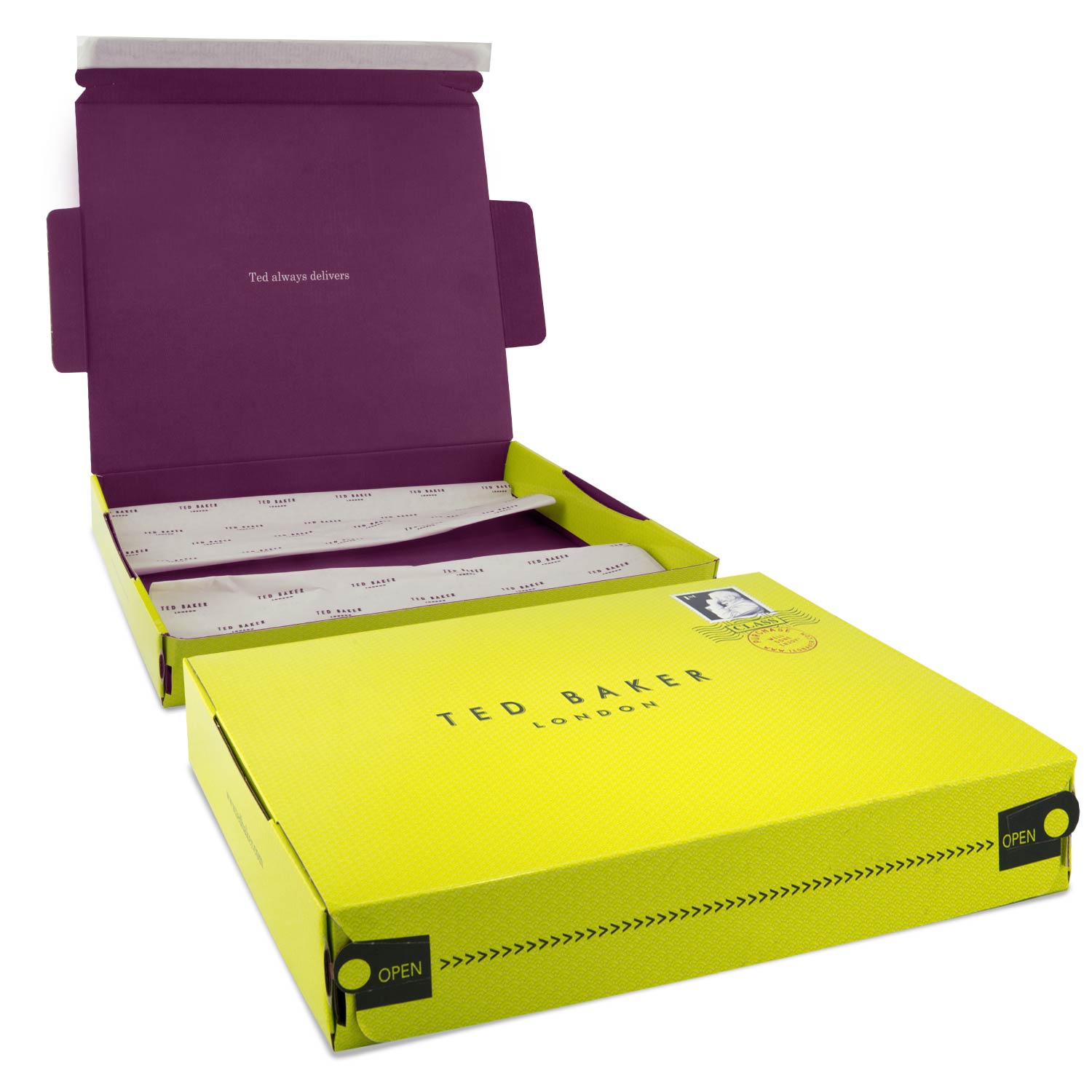

Bringing manufacture home by solving the ‘UK made’ criteria was the easy part since Lil has proudly been manufacturing exclusively in Cambridgeshire since its origins in 1983. The tricky part was in providing a comparably high-level of gloss sheen to gloss-plastic lamination. We did this by substituting litho lamination to high quality flexographic printing with a water-based gloss varnish coating.

Plastic Lamination of cardboard is so destructive to the recycling loop because the two substrates can never again be separated. While Ted Baker’s original intension to enable the boxes to have a secondary-use as a ‘keep sake’ box, the reality was that very few of their consumers were keeping them forever, thus a decade of their previous web boxes had almost all gone to either landfill or incineration. This is no longer the case today while Ted’ boxes enjoy one of the highest rates of sustainability in the global fashion market.

Lil’s famous peel & seal application was the perfected solution to the need for using clear plastic flow-wrapping to seal each box. The fulfilment team at the Park Royal Distribution Centre were relieved how much faster it made the packing process having only tried clear parcel tape in the past which was both slow and messy, and ruined the brand experience.